Recognizing Dielectric Transformer Oil: Necessary Advantages and Uses

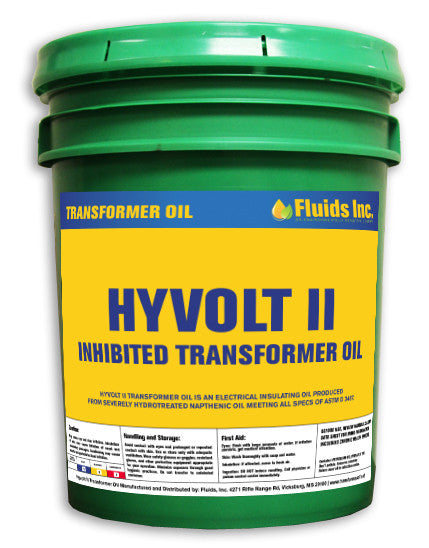

Dielectric transformer oil serves as a critical component in the procedure of electric transformers and high-voltage equipment, functioning largely as an insulating medium. As we explore the multiple benefits and uses of dielectric transformer oil, one have to think about how its function influences not simply equipment dependability, yet likewise broader operational factors to consider.

What Is Dielectric Transformer Oil?

Dielectric transformer oil is a specific protecting fluid made use of in electrical transformers and other high-voltage electrical tools. Unlike conventional oils, dielectric oil is particularly created to have high dielectric stamina, which allows it to withstand considerable electrical stress and anxiety without conducting power.

Normally originated from mineral oil or artificial sources, dielectric transformer oil satisfies rigorous sector requirements for purity and efficiency. Its chemical make-up is carefully designed to lessen the danger of oxidation and deterioration gradually, which is critical for maintaining the oil's insulating residential properties.

In enhancement to its shielding attributes, dielectric transformer oil serves as a coolant, absorbing and transferring heat produced by electrical parts during procedure. Overall, dielectric transformer oil is a necessary element in the secure and reputable procedure of electrical facilities.

Key Advantages of Dielectric Oil

While dielectric transformer oil offers critical functions in electrical systems, its benefits prolong past mere insulation and cooling. Among the main advantages of dielectric oil is its high dielectric strength, which efficiently protects against electrical failure, ensuring the safe procedure of transformers and other high-voltage tools. This property is important in keeping the dependability and durability of electrical systems.

Additionally, dielectric oil has superb thermal conductivity, permitting reliable warmth dissipation. This quality decreases the danger of getting too hot, hence prolonging the life expectancy of transformers and decreasing upkeep costs. The oil's chemical stability and resistance to oxidation add to its durability, making sure regular efficiency over time.

One more substantial advantage is its capacity to subdue arcing and corona discharge, which can damage electric components. By supplying a secure medium for electric power transfer, dielectric oil enhances functional safety.

Applications of Dielectric Transformer Oil

Dielectric transformer oil plays a pivotal role in different applications within the electrical industry, primarily because of its distinct shielding and cooling down homes. Among its key usages is in power transformers, where it offers to facilitate and shield internal elements heat dissipation. This is important in keeping functional performance and durability.

In enhancement to power transformers, dielectric oil is likewise made use of in circulation transformers, ensuring reputable and secure power distribution. Its high dielectric strength redirected here avoids electric discharges, therefore lowering the threat of failures and enhancing system dependability. In addition, dielectric transformer oil is employed in reactors and capacitor banks, where it executes comparable functions, protecting sensitive devices from electric breakdown - used transformer oil.

Upkeep Factors To Consider

Proper upkeep of dielectric transformer oil is necessary to make certain optimal efficiency and durability of electric equipment. Routine tracking of the oil's physical and chemical buildings is essential to detect any kind of degradation that might harm the insulation and cooling abilities. Secret criteria to assess include dampness content, acidity, and dielectric toughness.

Regular tasting and lab analysis can identify the visibility of pollutants such as dissolved gases, particulates, and oxidation by-products. These evaluations help in determining the oil's problem and whether it calls for therapy or replacement. Purification systems can be used to get rid of particulates and moisture from the oil, restoring its protecting homes and prolonging its life-span.

Additionally, preserving correct operating temperature levels is important; excessive heat can increase oil degradation (electrical insulating oil). Implementing temperature tracking systems can assist in finding overheating conditions early

Environmental Impact and Safety And Security

In evaluating the ecological effect and safety of dielectric transformer oil, it is imperative to think about both its composition and potential dangers. Typically acquired from mineral or synthetic sources, dielectric oils can differ dramatically in their environmental footprint. Conventional mineral oils, while efficient as insulators, may posture dangers if launched into the environment, as they can infect soil and water. On the other hand, naturally degradable synthetic oils provide an even more eco-friendly alternative, minimizing the threat of ecological damage in instance of spills or leakages.

Safety and security issues mostly rotate around flammability and toxicity. Dielectric oils can be combustible, demanding appropriate storage space and taking care of treatments to reduce fire risks. Certain additives made use Visit Your URL of in transformer oils might present toxicological risks, highlighting the importance of choosing oils with favorable security profiles.

Regulative compliance is additionally vital (transformer oil recovery). Complying with ecological laws and security criteria makes certain that using dielectric transformer oils minimizes adverse effect on human wellness and the environment. In verdict, recognizing the ecological implications and safety protocols connected with dielectric transformer oils is essential for liable usage in electric applications

Conclusion

In recap, dielectric transformer oil serves as an essential part in boosting the safety and security and performance of electrical transformers and high-voltage devices. Consideration of ecological influence and safety and security more underscores the significance of dielectric transformer oil in contemporary electrical infrastructure.

Dielectric find out here transformer oil offers as an important part in the operation of electric transformers and high-voltage devices, working mostly as a protecting medium. Dielectric transformer oil is a specialized protecting liquid utilized in electric transformers and various other high-voltage electric equipment. Unlike traditional oils, dielectric oil is specifically developed to possess high dielectric stamina, which enables it to endure substantial electrical stress without conducting electricity.

One of the main benefits of dielectric oil is its high dielectric toughness, which efficiently avoids electric failure, ensuring the safe procedure of transformers and other high-voltage equipment.In summary, dielectric transformer oil serves as an essential part in enhancing the safety and efficiency of electrical transformers and high-voltage equipment.